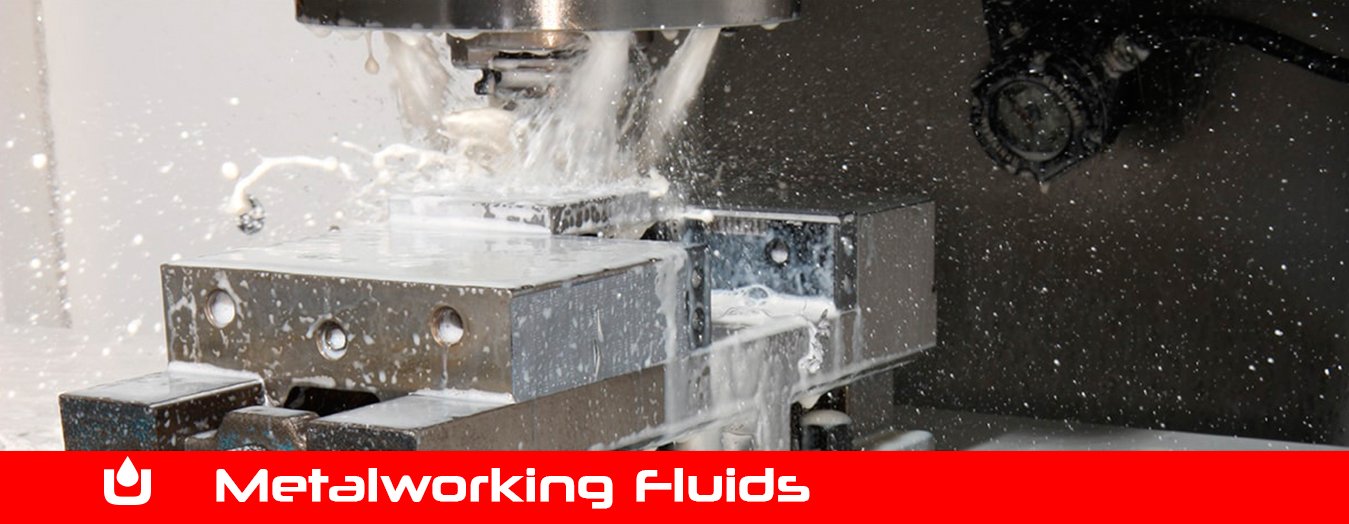

METALWORKING FLUID

Brautek’s metalworking fluids are recognized for its superior performance and for its range of applications and solutions tailored for a find more large variety of substance abuse benefits operation conditions and environments. Increased productivity and reduced operating costs are the results of using products with innovative and proved technologies like Brautek’s cutting oils.

Our products, along with the our service and support, ensures increased efficiency and profit in your metalworking industry.

METALWORKING FLUIDS

PRODUCTS

SAGAR

SAGAR is a full synthetic water-solution cutting fluid. Its nitrite free formulation is specially developed for cutting operations of steel cast iron and aluminium aleations giving excelent levels of surface finish.SAGAR is characterized by its highly stable translucid opalescent solution and by its excellent anticorrosive properties. This olorless water-solution has long life and low levels of foam and evaporation. SAGAR due to its heat transfer coeficient power and lubricity properties, improves significantly the cooling of the cutting tools and keeps the machining areas clean of waste material.

AFTON

AFTON is a cutting fluid, emulsifiable in water. It is a nitrite-free synthetic blend, specially developed for operations of grinding and machining of steel and cast iron, giving a high level of superficial finish.

AFTON presents a highly stable opalescent emulsion. Its lifetime operation is much longer than conventional products. It is completely anticorrosive at concentrations of 3%, giving an excellent protection to machines and their parts.

AFTON due to its high moisturizing power, it significantly improves the cooling of the cutting area and keeps the machines clean of micro-chips coming from machining and grinding.

OLCUT

OLCUT is a high quality mineral oil that contains additives emulsifiers and anti-rust for the rapid formation of emulsions highly stable with water and that confer properties against wear, rust, foam and the growth of fungi and bacteria. Thanks to its special formulation, and contrary to most products of this type, its rust protection improves by increasing the pressure of water, without affecting the emulsion stability.

OLCUT is recommended in the operations of metal machinery where is necessary to cool the cutting tool, such as drilling, turning, sawing, brushing, drilling, grinding, welding electromagnetic parts, etc.

QUENCH OIL

QUENCH OIL are high-quality oils developed for heat treatment of ferrous metals in a wide variety of quenching operations. They are formulated to provide deep and uniform hardening with minimum distortion and cracking. Quench Oils are available in three grades: 22, 22HS and 32HS.

The 22 grade is a highly refined, straight mineral oil recommended for conventional quenching of ferrous metals at bath temperatures up to 150°F (66°C). It has a slower quench speed than the other grades, and provides minimum hardening power. The HS grades are fortified with select additives to provide enhanced oxidation resistance and metalwetting ability for use in fast quench operations where it is important to develop maximum hardness while minimizing distortion. The 22HS grade is a medium and high speeds quench oil with moderateto-high hardening power. The 32HS grade is a higher viscosity, highspeed quench oil that provides the highest hardening power.